Is it Advisable to go for a Cooker ?

As the Indian Rice Milling Industry continues to grow steadily, the demand for Good and consistent quality of Parboiled Rice is also increasing. In recent times millers have preferred to set up plants of much higher capacities, specially to cater to the needs of the export market.

The quality requirements for the Parboiled Rice in the International market is that of rice with UNIFORM color. In the conventional parboiling processes, it is challenging to maintain the uniform color of rice as the steaming process is a batch process.

Batch Process :

In the batch process of parboiling, the steaming of paddy is done in parboiling tanks having a capacity of between 2 to 4 Tons. As it takes 6-10 minutes to steam the total batch, the paddy nearest to the perforated steam pipes tends to get darker in color and the paddy furthest from the steam pipes remains whiter.

Due to this the finished product is not uniform in color.

It is commonly observed in the process industry that uniform quality can be achieved by converting a process from a batch process to a CONTINUOUS process. The solution to get uniform quality of parboiled rice also lies in opting for a Continuous Steaming, continuous flow Paddy COOKER.

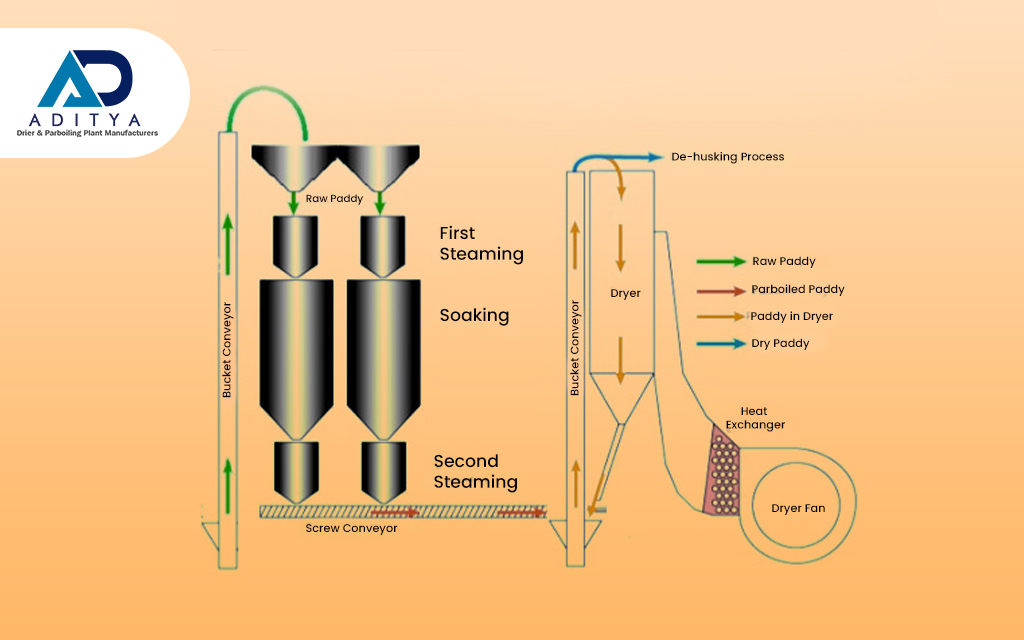

Process of The Paraboiling Rice :

In the modern Parboiling Plant with an inline COOKER, the soaking of paddy is done in tanks of much higher capacity – 10 Tons to 15 Tons per tank. This decreased the total number of tanks required and make the operation much easier.

After the soaking of paddy is completed, the water is drained and the soaked paddy is fed continuously through a conveyor to the COOKER. To maintain uniform steaming of Paddy, multiple steaming points are arranged in the cooker.

The flow of paddy through the cooker is controlled by a set of Rotary feeders. These are fitted with a Variable Frequency Drive to factor in for all varieties of paddy.

The next question which comes is what is the ideal Capacity of a COOKER, in terms of the Paddy Flow rate. Traditionally Cookers were designed with a flow rate of 10 Tons per hour of Paddy. This meant that to load a Drier of 50 Ton capacity, it would take 5 hours. This was not acceptable as the Drier idle time is increased and the productivity comes down drastically.

We at ADTPL took up the task of designing a HIGH CAPACITY Paddy COOKER and went on to design, manufacture and install COOKER Plant suitable for capacities ranging from 60 Tons to 100 Tons.

This is fast emerging as the best possible solution for Parboiling Plants of Higher capacities.

Let us take an example of a Rice Mill requiring Parboiling Equipment having a capacity of 80 tons per batch. In the conventional Parboiling method, the miller would have required 16 to 20 Parboiling Tanks.

With the modern concept of the COOKER Plant, the miller can opt to install 6-8 parboiling tanks of higher capacity coupled with an inline continuous COOKER. This greatly helps in the ease of operation and also helps to ensure uniform steaming of Paddy resulting in the uniform color of rice.

To summarize, the choice of installing a continuous COOKER for the Parboiling Plant is very beneficial for the processing of the parboiled paddy. The key benefits are :

1. Uniform Steaming of Paddy reducing steam losses

2. Uniform COLOR of Parboiled rice most suitable for EXPORT

3. Lesser number of Tanks resulting in lesser manpower requirement.

4. Lesser space requirement.

Despite all the advantages, not all millers are choosing this option. Let’s look into the reasons behind this :

LACK OF AWARENESS : As there are very few manufacturers who have the technical know-how, design capabilities, and infrastructure to design, manufacture and install such high-capacity COOKERS, most millers are not aware of this option.

HIGHER INITIAL INVESTMENT : The higher capacity Parboiling and Drying Units are at most times more expensive due to the Design requirements.

Considering all the above it is suggested that the millers study this option and opt for the highly efficient COOKER Plant in their Parboiling Equipment.